AT A GLANCE

- COMPANY: Sofrimar

- ESTABLISHED: 1979

- LOCATION: Kilmore Quay, Co. Wexford

- FOOD SECTOR: Seafood Processing

- MARKET: B2B Europe, US & Asia

- PRODUCTS: Shellfish & Whitefish

- NO. OF EMPLOYEES: 130

OVERVIEW

When Sofrimar’s management team first engaged with Diomac, in 2013, they were riding the crest of a wave. Having twice won the accolade of ‘Irish Seafood Exporter of the Year’, the owners had just been shortlisted in the ‘Ernst & Young Entrepreneur of the Year Awards. This period in Sofrimar’s growth coincided with new EU food labelling directives and massive reform of the fish industry with the roll out of the EMFF Operational Programme (2014-2020). This EU funding initiative sought to implement more regulation and control regarding sustainability and traceability while also supporting local fishing communities. The success and rapid growth of the company, together with increasingly stringent EU regulations, brought new challenges that highlighted the constraints of existing systems for managing information.

Sofrimar products are available in live, fresh, frozen, frozen at sea and cooked formats.

INTRODUCTION

Embracing Tradition, Technology & Sustainability

Sofrimar is an internationally acclaimed company specialising in the processing of premium seafood including Scallops, Whelks, Langoustine, Brown Crab and Blue Lobster – choices that span generations of fishing heritage. Working in close partnership with the local fishing community, Sofrimar has established a loyal supply base of over 200 vessels.

Through a dedicated Research and Development facility, along with constantly monitoring market changes, Sofrimar built up a strong track record in developing and launching new and innovative products. Sofrimar has always shown a passion and commitment to embedding sustainability into all aspects of its business and is a member of Ireland’s pioneering food and drink sustainability programme, Origin Green.

THE CHALLENGE

Addressing Fragmented Systems & Regulatory Pressures

Managing business requirements within the constraints and limitations of Sofrimar’s initial information systems became increasingly frustrating, particularly when dealing with new commercial and legal requirements. Fragmented systems became inefficient, slowing down production, requiring multiple entries and the widespread use of paper forms and excel sheets. This led to a state of disarray with data duplication and discrepancies. Sofrimar sought to ensure that the strict food product traceability and labelling requirements of regulatory bodies and customers were met consistently, without undue disruption to productivity. Renowned for recognising the potential of technological advances, Sofrimar set out to find a complete ERP solution that would enhance its excellent international reputation for supplying quality seafood products and secure the long-term future of the business.

Straight from the Sea to Sofrimar

THE SOLUTION

Seafood Industry Specific

The Sofrimar team, led by the Quality Manager and the Finance Director/Owner, worked collaboratively with the DIOMAC software development and project management teams. Successful implementation required DIOMAC to have the software development capability but also to draw on extensive expertise and knowledge of the Seafood Industry, Hardware Integration and Food Labelling regulations and technology. Sofrimar received advice and guidance from DIOMAC ERP Specialists throughout the process while building internal team capability towards independence.

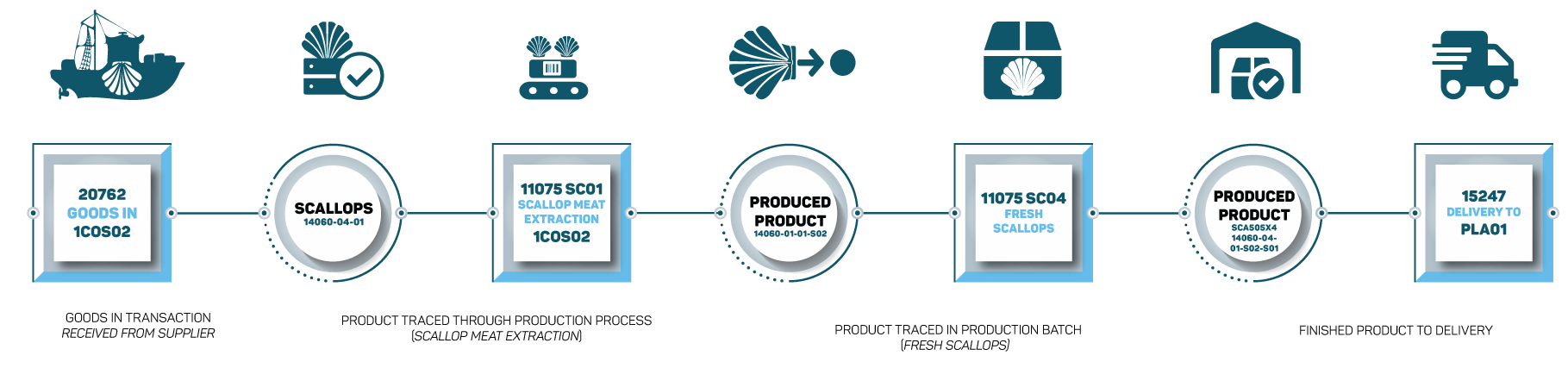

In addition to capturing and managing information for all aspects of the business, a completely traceable shellfish processing solution was systemised. Sofrimar now has full visibility of its fish manufacturing business with exceptional quality and financial control.

DIOMAC DELIVERED

A complete ERP Seafood Processing Solution for Production, Traceability, Labelling, Accounting and Reporting

- Fish Factory add-on, certified for E-LOCATE Scheme by GS1 and approved by SFPA.

- Weekly fishermen batch payments management and bank payment file upload.

- Single system platform for data management and reporting.

- Instant digital tracing map and waste recording at each process

- Real-time electronic weighing/recording/labelling of fish intake to EU regulatory standards.

- Dynamic label printing and flexible label templates automatically linked to batch information.

- Flexible option to pay for products based on Intake weight or graded weight.

- Production yield reporting by process and production batch.

- Sales notes – Automated export facility per vessel to DAFM web portal.

- Automated weekly KPI reports and timely monthly management accounts.

SOFTWARE SYSTEMS YOU CAN TRUST

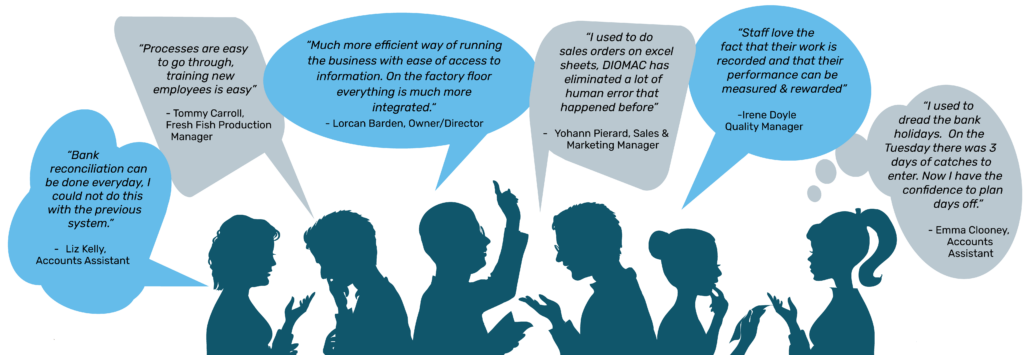

“Moving away from our old software system was a big decision for us but the support throughout the implementation and go live process was excellent. Since then, our relationship with the Diomac team has grown and they are definitely a resource we value and trust.”

– Lorcan Barden – Owner & Finance Director

THE BENEFITS

The perfect fit and complete ERP Solution

Sofrimar now has best-in-class product traceability throughout all its operations. They can easily conform to and often exceed standard legislative and customer requirements.

Their investment in DIOMAC’s complete ERP Solution, including a bespoke version of Factory Touch, not only significantly improved administration and paperwork but also reduced Sofrimar’s product recall response time by 97%.

The elimination of multiple data entries has resulted in huge time savings and fewer errors and has built a robust and cohesive team environment.

SOFRIMAR’S GAINS

Key benefits gained by Sofrimar after partnering with DIOMAC

- Secured IFS Food Certification with best-in-class digital traceability mapping.

- Waste monitoring enables compliance with Origin Green membership requirements.

- Product traceability check time reduction from 3 hours average to less than 5 minutes, requested by regulators.

- Sofrimar were approved for E-LOCATE financial assistance.

- Fishermen receive instant landing reports and prompt weekly payments.

- A significant reduction in the financial month end process from 20 days to 8 days.

- Time reduction in generating reports allows management to concentrate on evaluating new projects and analysing key information.

- Easily accessible, relevant and reliable information for customers and auditors.

Seamlessly Connected and Traceable from Catch to Dispatch.

THE RESULTS

Weathering All Storms

Today, Sofrimar reaps the benefits of having one complete ERP solution to manage all its operations with a single source of data. This has enabled them to streamline their seafood processing business, maintain excellent relationships with their suppliers and explore new markets.

Sofrimar’s vision is to build sustainability into all aspects of its business operations. They pride themselves on their ability to marry tradition with modern technology. In challenging times, the digitalisation of their business operations has allowed them to navigate the choppy waters of global trading with full product and financial visibility.

REQUEST A DEMO

DIOMAC empowers you to grow your business with a fully connected team that achieves superior performance levels with instant product traceability and total visibility of operational performance and profitability.

SOFRIMAR CASE STUDY PDF

Find out how Sofrimar built a sustainable business by investing in DIOMAC ERP